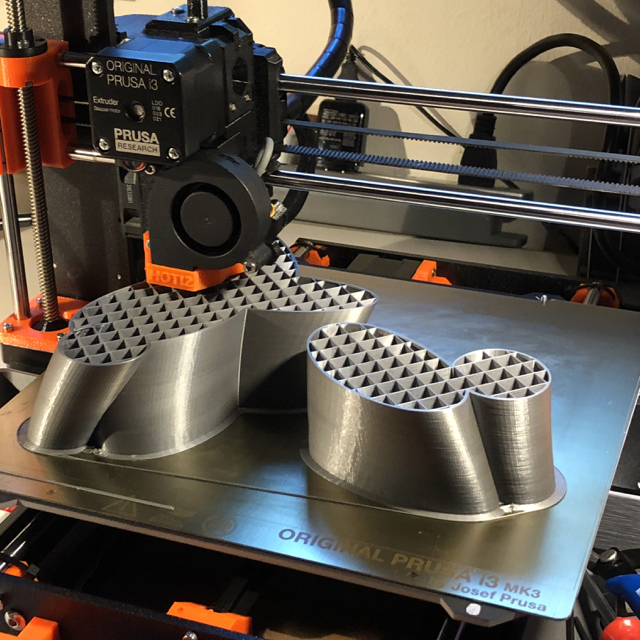

Perhaps the most amazing thing about the FDM interaction is the way that it very well may be, and is, utilized to make completed parts. FDM parts are produced using a powerful ABS mix of mechanical evaluation thermoplastics that is really more grounded than standard ABS What is more, FDM parts can be smoothed, sanded, machined and painted to convey parts that can be placed into utilization right away. In situations where the parts are painted, it is extremely difficult to differentiate between a FDM and a shaped plastic part

Many are presently alluding to this immediate assembling measure as DDM Direct Digital Manufacturing. DDM can help your organization see numerous advantages. Here are only a couple:

- Rapid Deployment – When a segments configuration is finished, assembling can start right away. Only minutes after the CAD information is finished, assembling can start in light of the fact that there is no creation delay while sitting tight for tooling.

- Low Capital Expenditure – Eliminating tooling not lessens time-to-showcase; it additionally decreases the expense for assembling. With DDM there is no requirement for tooling. Accordingly, the underlying money cost to increase fabricating is drastically diminished.

- Unlimited Complexity – DDM advances the plan of parts for the best presentation. Since FDM 3d printing leaves behind an added substance manufacture measure, as intertwined testimony demonstrating FDM, the plan unpredictability is limitless.

- Freedom to Redesign – Equally amazing to the plan opportunities offered by DDM are the freshly discovered opportunities to overhaul a section whenever in the item lifecycle and as frequently as wanted. Since tooling has been wiped out, there is definitely no punishment for item updates.