Prototyping is the way toward making an example item model to be tried in reality climate and to fill in as a reason for different cycles. Conventional prototyping includes planning, creating, constructing and manufacturing a model of our item, normally by fashioners and engineers utilizing pen, pencil and paper or a CAD plan programming document; while rapid prototyping includes 3D added substance printing of the scaled model of the part or gathering utilizing a 3D printer and a 3D added substance layer fabricating innovation, without assembling measure arranging or tooling. Prototyping is the plan check and change period of item advancement since it demonstrates and exhibits the plan. We need to have the option to contact and feel, test and show an item before really fabricating it either in large scale manufacturing or from a costly material and we need to ensure our plan suits our necessities and applications.

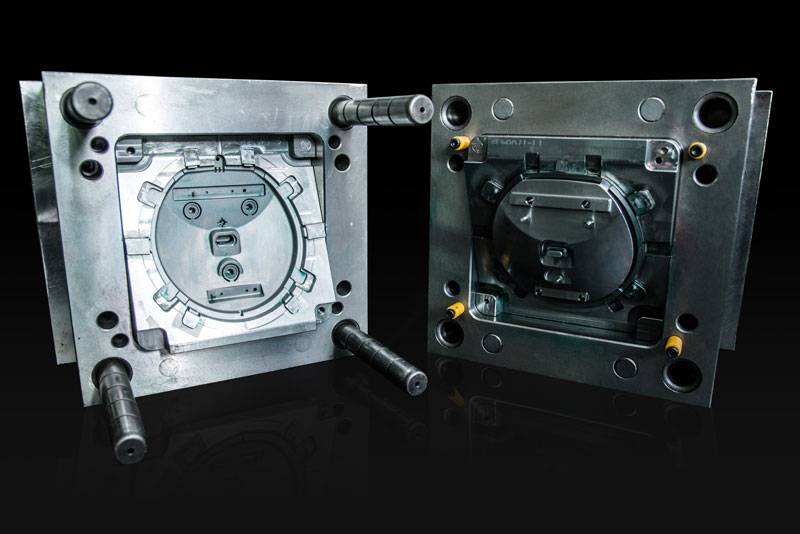

It empowers us to show and show the new item, either to our administrators, our financial specialists, our creators or potentially our clients. It lets us test our thoughts and ideas to check whether it can really work in reality just as to test the plan to check whether it passes all the necessities testing. We can likewise utilize a model to assess if and where we have to direct upgrades and changes if fundamental. We can assemble a fractional model or we can manufacture the genuine part itself, looking and feeling as the total item. It may work or not, or it may just capacity incompletely for testing just bits of the plan. The last form will presumably look right and capacity accurately. The customary rapid tooling company strategy incorporates a model manufacture of various materials, including dirt, froth, wood, plastics and metal. It can have extra materials to it, for example, wires, tape and so on We can make if by hand – cutting, sticking, taping or we can manufacture it with CNC processing machines.

Then again, rapid prototyping incorporates innovation that makes the 3D part from the CAD record itself no paper plans on a PC and 3D printer, utilizing materials, for example, ABS, PLA, PETT, HIPS, HDPE, PVA, tar, pottery, nylon, hardened steel and that is just the beginning. 3D printing is turning out to be more mainstream as of late because of the way that we can control speed and precision of the manufactured parts with it, and we can make profoundly complex models with it that we probably won’t have the option to if machining. The part made with a 3D printer can be practically indistinguishable from how the end result will resemble, therefor giving a greatly improved feeling of the genuine article. Likewise, there is considerably less waste material in 3D printing and it is typically an undertaking for one individual, consequently getting a good deal on work force and staff.